For the interstage and final cooling in piston, compressors have to fulfil specific requirements. [12].

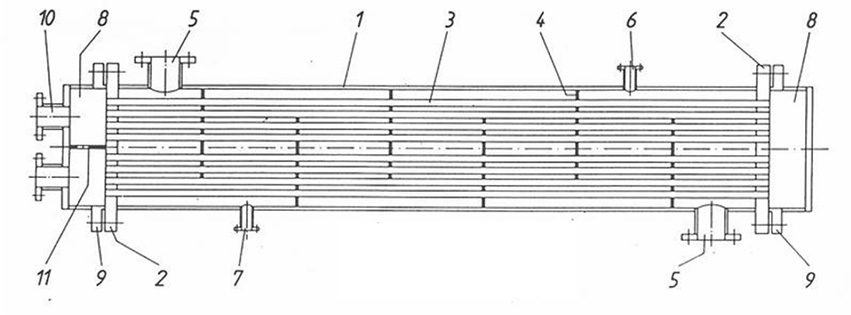

The most important type for low and middle pressure range are the tube bundle heat exchanger, see Figure 4.10.

For the interstage and final cooling in piston, compressors have to fulfil specific requirements. [12].

The most important type for low and middle pressure range are the tube bundle heat exchanger, see Figure 4.10.

Figure 4.10: Tube bundle heat exchanger [0]

It consists of a cylindrical outer shell (1), closed on its end by covers (8) and the bundle of tubes (3), which in turn is usually closed on its ends by two flat plates (2). For bundles of tubes fastened on both ends special constructions are necessary to avoid buckling reduce bending (for example a design to provide compensation for the elongation of the tubes, an axially movable cover (floating cover) or U-tubes with only one cover plate). Normally, the coolant is led through the tubes and the gas, diverted by baffles, flows in the opposite and cross direction of the coolant flow, [13 – 15].

In the low-pressure range, also air-cooled tube coolers are being used. The tubes are close to each other and are fitted with cooling fins. In the high-pressure range double tube coolers, with the gas flowing through the inner tube, are the preferential design. A simple design is the helical coil tube cooler, where the gas is led through a helical coil tube (sometimes also in parallel for several stages) through the hardly moving cooling liquid. It is mainly used for small volume flows and high pressures.

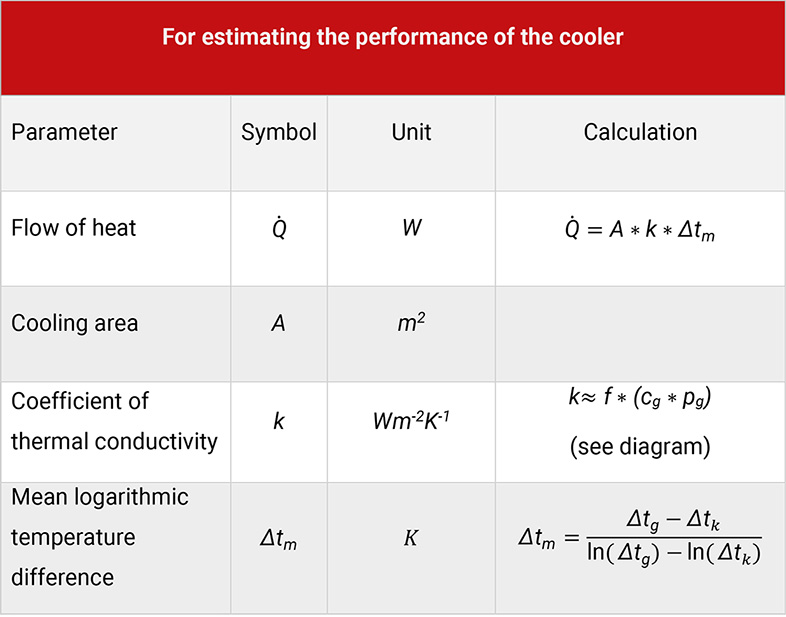

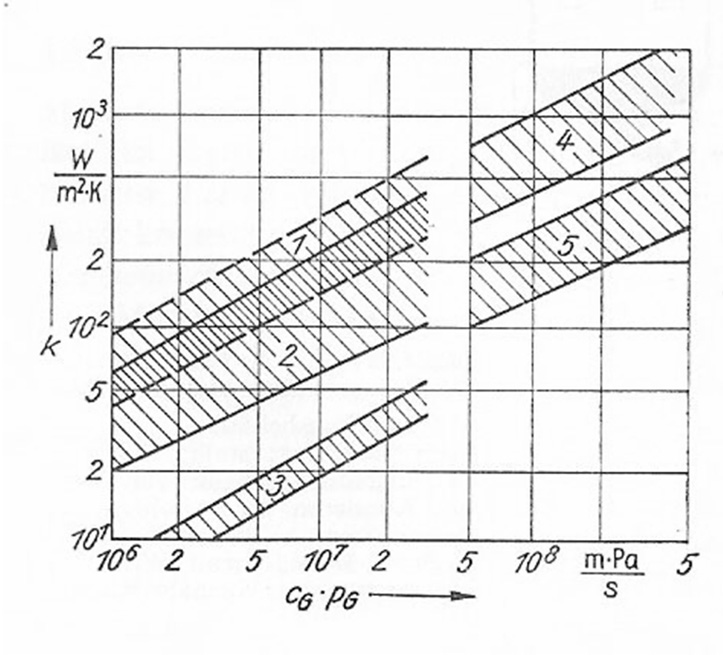

The calculation of the cooler starts with the following correlation between the main parameters, see Table 4.5.

Table 4.5: Equations to estimate the performance of the heat exchanger

For the heat flux the compression work done in a stage represents the upper limit. For approximations, values from practical experience for the coefficient of thermal conductivity can be used. The diagram as shown below relies on the assumption that the heat flow depends mainly on the heat transfer on the gas side. This heat transfer can be calculated for all types of coolers (1, 2 tube bundle, 3 tube, 4 double tube, 5 helical coil tube coolers) approximately as a function of the product of gas velocity cG and pressure pG.

Figure 4.11: Diagram for different type of coolers [0]

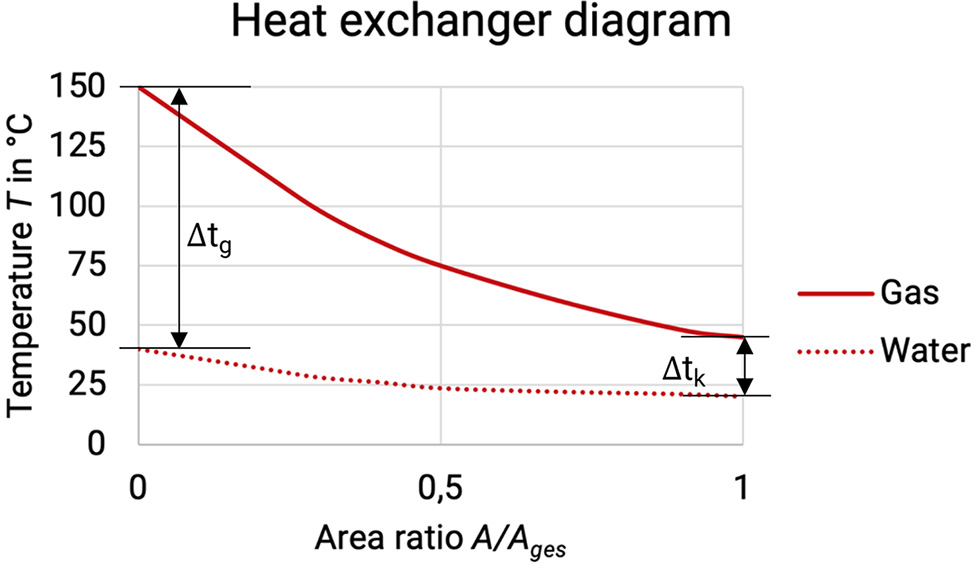

The mean logarithmic temperature difference between gas and coolant at equal inlet temperatures will be the lower if the gas outlet temperature gets closer to the coolant inlet temperature, see Figure 4.12.

Figure 4.12: Temperature-area diagram of a heat exchanger [33]

Table 4.6 shows the special features with heat exchangers in piston compressor installations.

Table 4.6: Special features of heat exchangers in piston compressor installations

The separation of droplets can be done either via the inertia or via the diffusion principle.

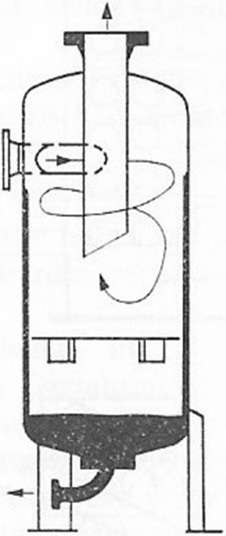

The cyclone works according to the inertia principle. By injecting the gas stream tangentially into the separator housing, a spin of the stream is created. The gas exits through the central tube at the bottom of the cooler, see Figure 4.13.

Figure 4.13: Inertia principle [0]

The radial moment of inertia is considerably higher for the droplets due to their higher density. This creates a relative motion of the droplets towards the outside, which slows down due to friction. The size of the droplets, for which a balance exists on the radius of the plunger tube between friction and inertia, is called the limit droplet diameter. Droplets with larger diameter will be separated on the outside diameter of the cyclone, from where they flow downwards as a liquid film towards the drainage at the bottom of the cyclone (drainage).

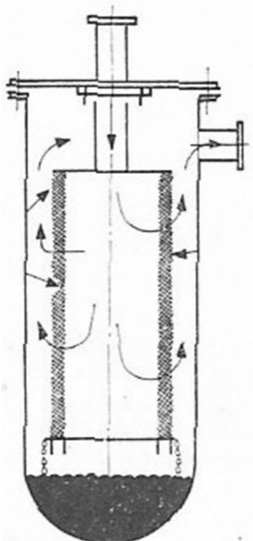

A separation according to the diffusion principle is carried out in fibre filters. The gas flows into the filter centrally and crosses the filter in a radial direction, see Figure 4.14.

Figure 4.14: Diffusion principle [0]

Due to the molecular motion (diffusion), a higher proportion of droplets will be separated than would correspond to the ratio of area taken up by the fibres compared to the total area of the filter. The result of the diffusion will be the more effective the longer the droplets remain inside the fibres package.

The limit diameter of droplets for fibre filters is considerably smaller than the one for inertia separators. Therefore, fibre filters are mainly used for fine separation, cyclones for crude separation.

The separation efficiency compares the mass flow of liquid which has been separated and the amount of liquid at the inlet. The separation efficiency of cyclones and other inertia separators (for example wire mesh filters or mesh deflectors) rises with the gas flow degressively. The overall pressure loss however rises progressively. Separation efficiency and total pressure losses of a fibre filter improve with lower volume flows. The selection and design of separators is an optimisation problem between separation efficiency, allowable pressure drop and costs.

If there is a requirement for very clean gas (e.g. special air installations, installations for gas separation and liquefaction) highly effective gas cleaning systems with refrigeration dryers will be installed. Most of the components of water or oil carried as vapour will be taken out of the gas.

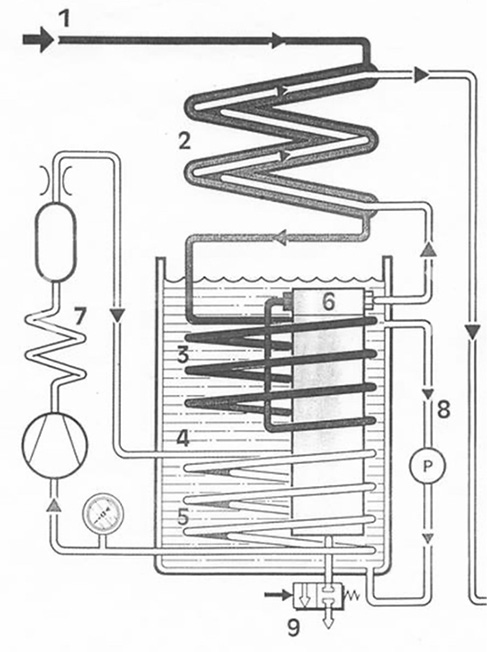

In refrigeration dryers, the gas with droplets flows through a bath of brine (4), which is cooled down by a refrigerator. The amount of liquid the gas can carry in form of vapour is thereby reduced and part of it will be separated as droplets. These are then taken out of the gas in the cyclone (6), which is an integral part of the design, see Figure 4.15.

Figure 4.15: Refrigeration dryer system [0]

In adsorption dryers, the gas with droplets flows through columns filled with porous material, on the large surface of which water molecules will deposit. Once the absorbers are saturated, they will be regenerated in a drying cycle by a partial flow of the dried gas.

2019, Delft, The Netherlands, Training workshop

„Basic Design and Operation of Reciprocating Compressors“

2019, Delft, The Netherlands, Training workshop

„Emissions of Reciprocating Compressors“

2019, Delft, The Netherlands, Training workshop

„Pulsations and vibrations in Reciprocating Compressors“

Material for download

B1 EFRC Training 2019 Typical Applications Bas Bruins

B2 EFRC Training 2019 Design Construction Niek Albers

B3 EFRC Training 2019 Thermodynamics Johannes Strecha

B4 EFRC Training 2019 Auxiliaries Bernd Schmidt

B5 EFRC Training 2019 Critical Compressor Components Paul Modern

B6 EFRC Training 2019 Condition Monitoring Jan Loeken

B7 EFRC Training 2019 Operations and Maintenance Rene Anke

S1-01 EFRC Training 2019 Emission Control Andre Eijk

S1-02 EFRC Training 2019 Emission Control Christian Hold

S1-03 EFRC Training 2019 Emission Rufus Bakker

S2-00 EFRC Training 2019 Introduction Leonard van Lier

S2-01 EFRC Training 2019 Fieldcase 1 Leonard van Lier

S2-02 EFRC Training 2019 pulsation theory Wijnand Schoemakers

S2-03 EFRC Training 2019 Fieldcase 2 Wijnand Schoemakers

S2-04 EFRC Training 2019 vibration theory Lennert Buijs

2018, Madrid, Spain, Training – 11th EFRC Conference

„State-of-the-art Design of Reciprocating Compressors“

Material for download

00 EFRC Introduction Peters TNO 2018 handouts

01 CompressorSizing HTC Niek Albers

02 Capacity Control Hoerb Klaus Stachel

03 LowHighSpeed SIAD Roberto Ravasio

04 Drivers Ariel Gregg Phillippi

05 Vibration Control TNO Andre Eijk

06 Foundations NEAC Harry Lankenau

2017, Delft, The Netherlands, Training workshop

„Condition Monitoring for Reciprocating Compressors“

2017, Delft, The Netherlands, Training workshop

„Foundation Design for Reciprocating Compressors“

2017, Delft, The Netherlands, Training workshop

„Condition Monitoring for Reciprocating Compressors“

Material for download

01 Program EFRC Workshop 2017 final

02.1 List of Participants 2017 EFRC

02.2 List of Speakers EFRC 13-14 september 2017

05 EFRC 2017 Basic training Typical applications

06 EFRC 2017 Basic training Thermodynamics

07 EFRC 2017 Basic training Design & Construction

08.1 EFRC 2017 Basic training Pulsations and Vibrations – PART 1

08.2 EFRC 2017 Basic training Pulsations and Vibrations – PART 2

09 EFRC 2017 Basic training Compressor valves & wearing parts

10 EFRC 2017 Basic training Auxiliary Systems

11 EFRC 2017 Basic training Installation & Maintenance

12 EFRC 2017 Specialized training Foundation design Dynamic loads

13 EFRC 2017 Specialized training Foundation design Soil interaction

14 EFRC 2017 Specialized training Foundation design Anchor bolts

15 EFRC 2017 Specialized training Foundation design Compressor skids

16 EFRC 2017 Specialized training Foundation design Grouting

17 EFRC 2017 Specialized training Foundation design Foundation repair & general overhaul

18 EFRC 2017 Specialized training Condition Monitoring Block 1

19 EFRC 2017 Specialized training Condition Monitoring Block 2

2016, Düsseldorf, Germany, Training – 10th EFRC Conference

„Lubrication and Wear in Reciprocating Compressors“

Material for download

00 EFRC Training Introduction Peters – TNO

01 EFRC Training NEAC Frame Lube

02 EFRC Training Emissions related to wear

03 EFRC Training Lubrication and Wear

04 EFRC Training Wear and Lubrication of Stuffing Boxes

05 EFRC Training Effect of wear and lubrication – Valves

06 EFRC Training Monitoring Wear

2015, Delft, The Netherlands, Training workshop

„Basic Design and Operation of Reciprocating Compressors“

Material for download

01 EFRC Training Applications where Recips are used

02 EFRC Training THERMODYNAMICS

03 EFRC Training Design & Construction

04 EFRC Training Compressor valves

05 EFRC Training Pulsations and Vibrations

06 EFRC Training Condition Monitoring

07 EFRC Training Installation Operation Maintenance

2014, Vienna, Austria, Training – 9th EFRC Conference

„Foundation Design for Reciprocating Compressors“

Material for download

EFRC Training 2014 Anchor bolts – HTC

EFRC Training 2014 DR compr forces [Compatibility Mode]

EFRC Training 2014 Skid Mounted Compressor 2 PSE

EFRC Training 2014 TNO [Compatibility Mode]

EFRC Training Vienna 2014 – Grout JAK R6 [Compatibility Mode]

EFRC Training 2014 NEAC

2013, Delft, The Netherlands, Training workshop

„Basic Design and Operation of Reciprocating Compressors“

Material for download

00 EFRC Introduction Peters – TNO [Compatibility Mode]

01 EFRC Training Compressors and Applications RonvdHandel

02 EFRC Training Comp Design and Construction – T.Heumesser [Compatibility Mode]

03 EFRC Training Introduction Thermodynamic – A.Allenspach

04 EFRC Training Critical components – wearing parts – Bernhard Spiegl [Compatibility Mode]

05 EFRC Training Pulsations and Vibrations – L. van Lier A.Eijk [Compatibility Mode]

06 EFRC Training workshop – Condition Monitoring rev FINAL – G. Rossi

07 EFRC Training Installation and Maintenance – H.Langenau [Read-Only]

2012, Düsseldorf, Germany, Training – 8th EFRC Conference

„Condition Monitoring for Reciprocating Compressors“

Material for download

0. EFRC Workshop 2012 Introduction Peters – TNO

1. EFRC Workshop General Design Elements – Prognost [Compatibility Mode]

2. EFRC Workshop Standard Instrumentation (GE)

3. EFRC Workshop Rider ring wear – Howden final [Repaired]

4. EFRC workshop Condition monitoring – Hoerbiger

5. EFRC workshop Allowable Pulsation & Vibration (A. Eijk) – TNO

6. EFRC workshop On Site Vibration – NEAC

2010, Florence, Italy, Training – 7th EFRC Conference

„Challenging Conditions for Reciprocating Compressors“

Material for download

0. EFRC Workshop 2010 Introduction Peters – TNO

1. EFRC Workshop 2010 Duineveld – TCS

2. EFRC Workshop 2010 van Lier – TNO

3. EFRC workshop 2010 Machu – Hoerbiger

4. EFRC Workshop 2010 Langela – Stasskol

5. EFRC Workshop 2010 Valaer – BCA

6. EFRC Workshop 2010 Ahlert – PROGNOST

2008, Düsseldorf, Germany, Training – 6th EFRC Conference

„Pulsations and vibrations in Reciprocating Compressors“

Material for download

1. TNO – Fundamentals

2. NEA – Effects Compr Performance

3. BCA – Effects on compressor reliability

4. Hoerbiger – Valves

5. TCS – Pulsations dampers

6. PROGNOST – Monitoring

2007, Prague, Czech Republic, Training – 5th EFRC Conference

„Capacity Control for Reciprocating Compressors“

Material for download

EFRC Workshop 1 TCS – Introduction

EFRC Workshop 2 NEA – Control options

EFRC Workshop 3 Burckhardt – Speed control

EFRC Workshop 4 Hoerbiger – Reverse Flow

EFRC Workshop 5 TNO – Pulsations

EFRC Workshop 6 Prognost – Monitoring

2022, Delft, The Netherlands, Training workshop

„Challenges in hydrogen compression“

2022, Delft, The Netherlands, Training workshop

„Basic Design and Operation of Reciprocating Compressors“

2021, Warsaw, Poland, Training – 12th EFRC Conference

„Trouble-shooting techniques for Reciprocating Compressors“

2019, Delft, The Netherlands, Training workshop

„Pulsations and vibrations in Reciprocating Compressors“

2019, Delft, The Netherlands, Training workshop

„Emissions of Reciprocating Compressors“

2019, Delft, The Netherlands, Training workshop

„Basic Design and Operation of Reciprocating Compressors“

This website uses cookies to offer you the best possible user experience. Cookie information is stored in your browser and performs functions such as recognition on your website and helps our team to understand which areas of the website are most interesting and useful for you.

You can customize all of your cookie settings by navigating to the tabs on the left.

Strictly necessary cookies should always be activated so that we can save your settings for cookie settings.

If you deactivate this cookie, we cannot save your settings. This means that you have to reactivate or deactivate cookies every time you visit this website.

More information about our Cookie policy here.