Within the energy transition, the use of hydrogen for mobility applications is a relevant option for decarbonization. To achieve this purpose, reliable Hydrogen Re-fuelling Stations (HRS) are required. For this specific use case, the compression shall be very clean, shall be able to reach high discharge pressure and shall be able to deal with intermittent conditions (multiple starts and stops). For this use case, among a limited number of alternatives techniques, the diaphragm compressor is a suitable candidate with a large industrial track record. However, in some industrial examples of HRSs, the reliability of the diaphragm compressors was found inadequate. In particular, a too high failure rate of the membranes was observed. In a first project phase (HyMem1), an inventory was made of the operational aspects that influence the reliability, along with lessons-learned and best-practices.

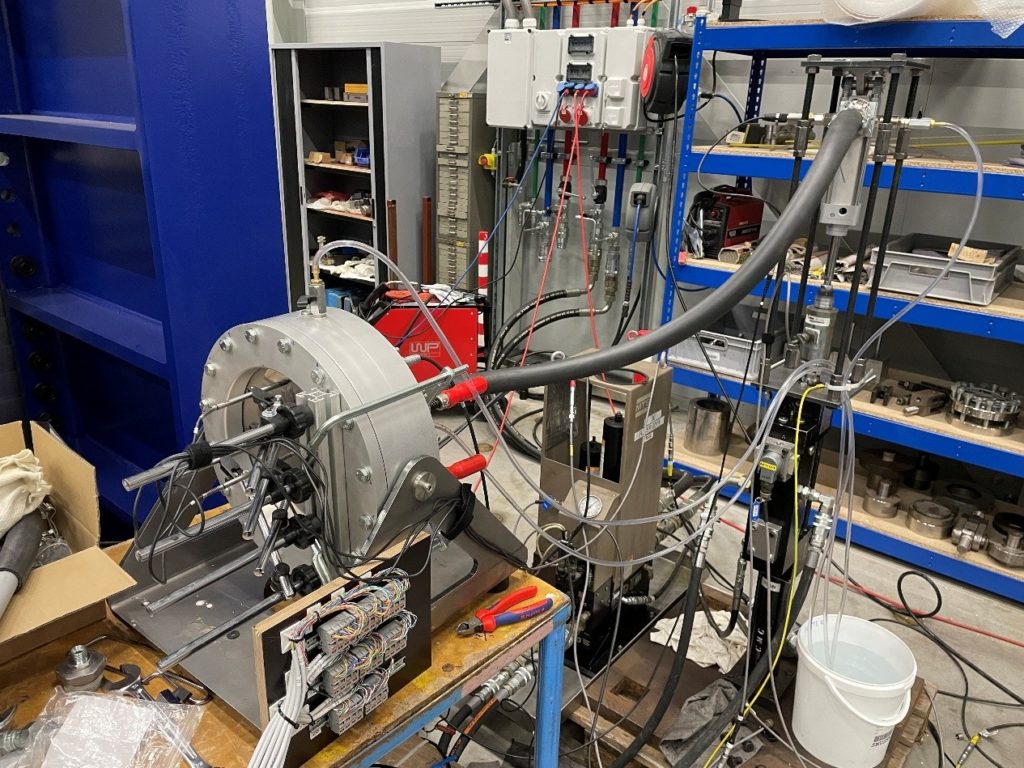

In MyMem2, experimental techniques were explored by laboratory tests, to analyze the dynamic membrane behavior. Such measurements will be a valuable source of information to study dynamic structural response of the membrane, to confirm root cause of failures and to validate numerical models. Also, systematic, simplified laboratory tests at lower pressure are considered an intermediate step toward dynamic membrane measurements in a real diaphragm compressor, at increased pressures.

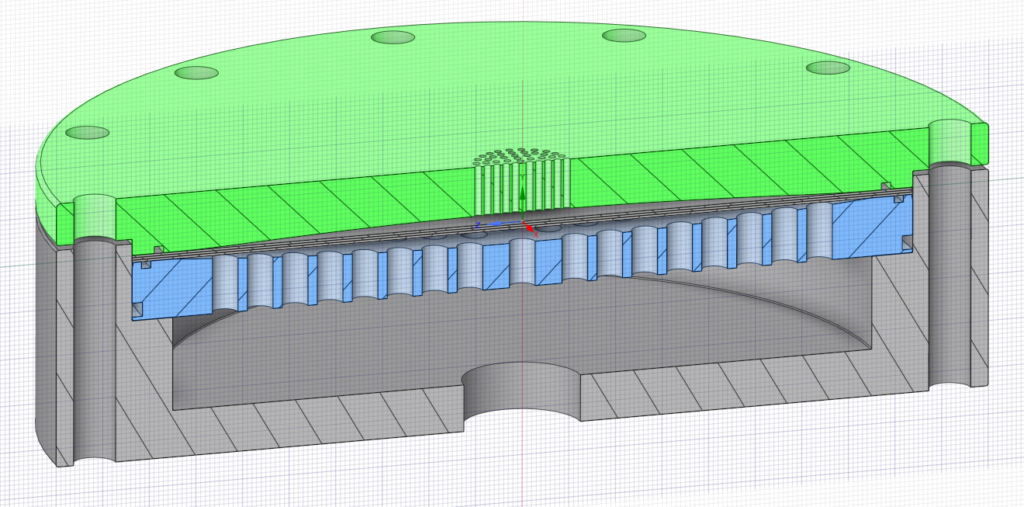

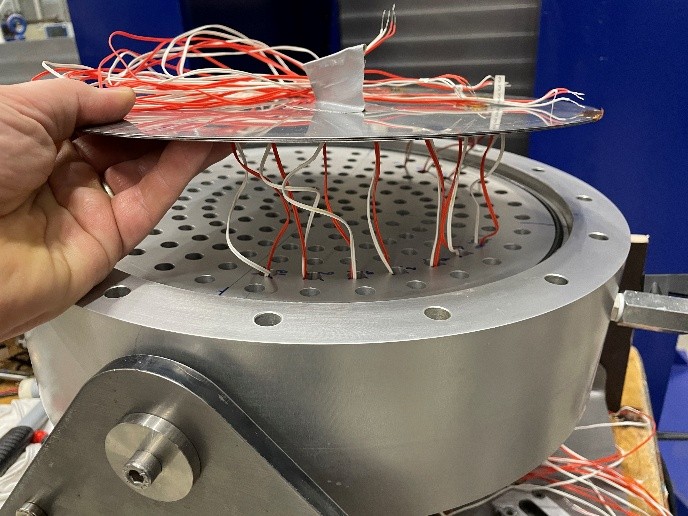

In a diaphragm head mock-up, designed for these tests, harmonic loading of test membrane was enforced with a hydraulic system. The membrane response (LVDT displacement sensors and dynamic stress with strain gauges at various spots on opposite locations of the membranes) was measured. The membrane properties were recorded at high sampling rate, along with the dynamic pressure and other operational parameters. The measurement techniques provide valid results, for membrane displacement and strain, up to a frequency of ~10 Hz. The laboratory tests also indicated that the membrane response may be significantly influenced by non-ideal clamping effects along the circumference, results in non-uniform membrane displacement.

The lessons learned in the laboratory tests, may be used in future tests in a real diaphragm compressor at increased pressure. The measurement data was shared with the EFRC R&D partners, and the mock-up of the diaphragm head was stored for future use by the group.