This study examines the structural performance of piston rods in reciprocating compressors, with a focus on the potential thermodynamic benefits of hollow rod designs. Piston rods are exposed to high compressive loads, making buckling a critical failure mode. Yet, even for conventional non-hollow piston rods, there is no unified industry standard for buckling safety values. Companies apply widely varying methods and safety factors. The absence of consistency highlights both the complexity of predicting buckling and the need for more in-depth investigation.

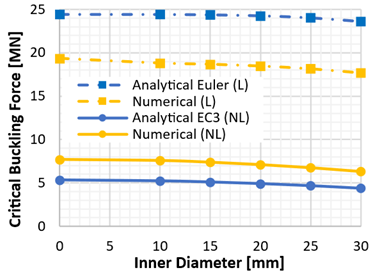

The research compares hollow and non-hollow piston rods using both analytical and numerical approaches, encompassing linear (Euler) and nonlinear (Eurocode 3) methods. Finite Element Method (FEM) simulations complement the calculations. Results show that for the analysed application-related piston rod, increasing the inner diameter of a piston rod (up to 50% of its outer diameter) has only a minor effect on buckling resistance. Hollow rods demonstrated only a 4% to 8% reduction in critical buckling force compared to non-hollow rods. Furthermore, nonlinear analysis provided more realistic safety margins than linear theory (see diagram), showing a significant difference between the two approaches.

These findings suggest that hollow piston rods may be employed to enable internal piston cooling of sealing elements and reduce the oscillating mass without significantly compromising mechanical integrity. Adopting hollow rod designs could extend component lifetime and enhance compressor efficiency if future design rules incorporate more realistic (nonlinear) safety calculations and account for the stresses from varying, real-life operating loads.